Study Guide

Incomplete Fusion

-

University:

California State University, Northridge -

Course:

MSE 528/L | Principles of Materials Engineering and Lab Academic year:

2021

-

Views:

109

Pages:

4

Author:

Hallie Randolph

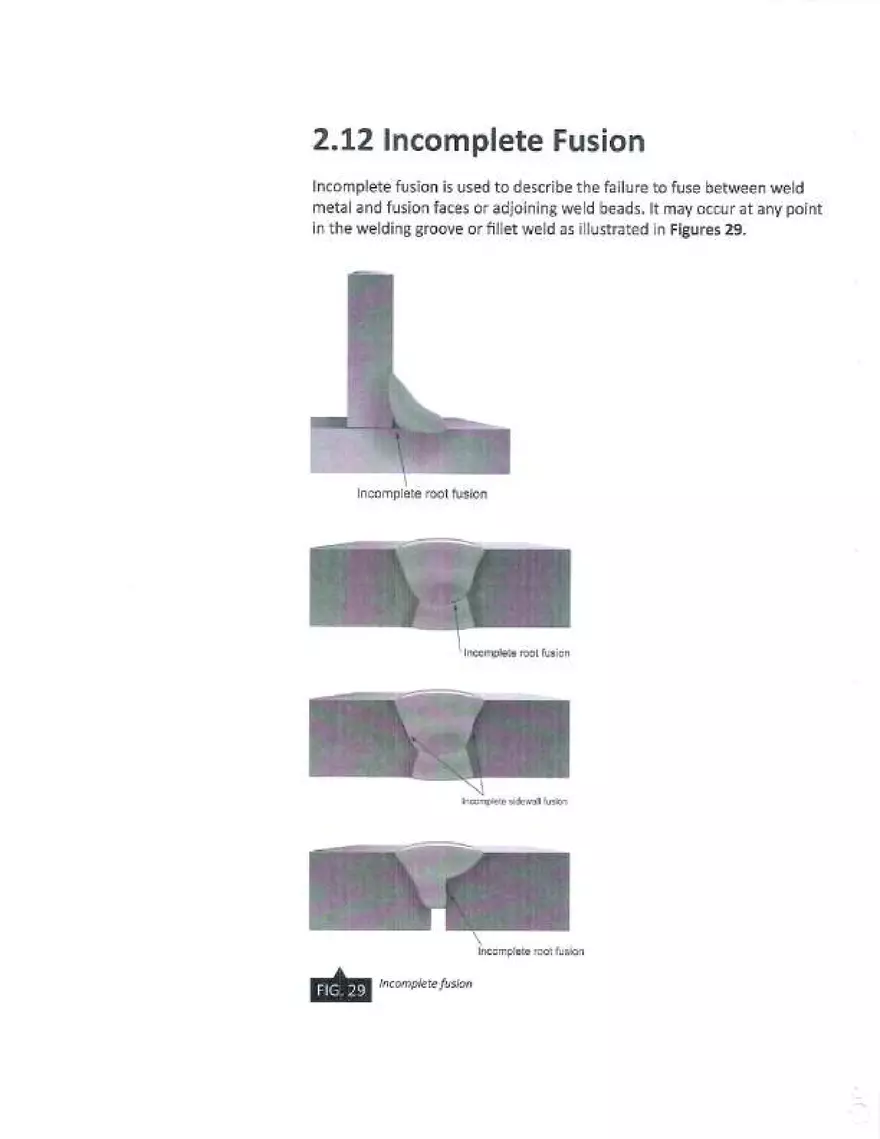

2.12 Incomplete Fusion

Incomplete fusion is used to describe the failure to fuse between weld

metal and fusion faces or adjoining weld beads. It may occur at any point

in the welding groove or fillet weld as illustrated in Figures 29.

Incomplete root fusion

Incomplete root fusion

Incomplete sidewall fusion

Incomplete root fusion cwbgroup

Incomplete fusion may be caused by a number of factors, either singly or

in combination. Some of these factors are listed below:

$

Improper electrode selection: selection of an electrode that is too

large for the joint preparation inhibits electrode manipulation

Improper welding parameters: welding parameters that are too low in

in current and/or voltage

Improper manipulation of the electrode: improper work or travel

angles and travel speed that is too fast

Improper cleaning of material: rust, oxides and mill scale that are not

removed from the joint prior to welding

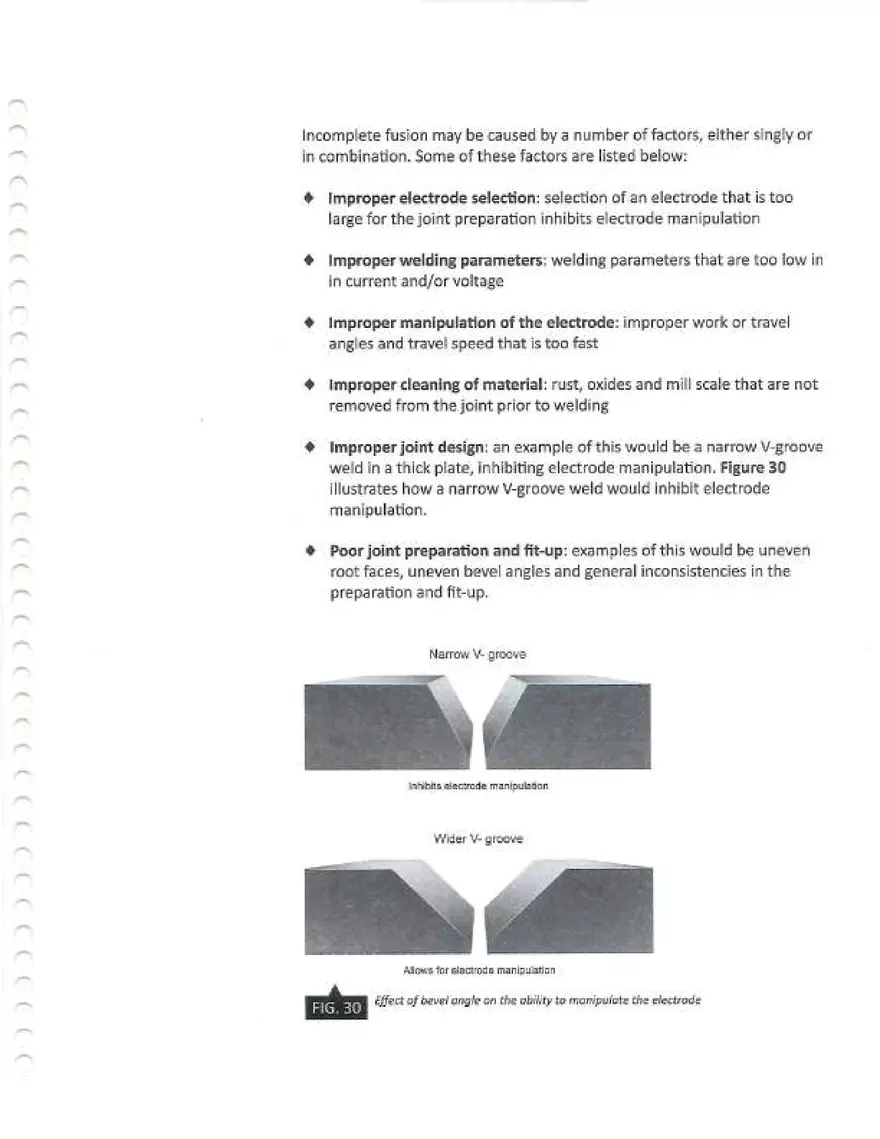

Improper joint design: an example of this would be a narrow V-groove

weld ïn a thick plate, inhibiting electrode manipulation. Figure 30

illustrates how a narrow V-groove weld would inhibit electrode

manipulation.

Poor joint preparation and fit-up: examples of this would be uneven

root faces, uneven bevel angles and general inconsistencies in the

preparation and fit-up.

Narrow V- groove

Inhibits electrode manipulation

Wider V- groove

Allows for electrode manipulation

riG.20|

Effect oƒ bevel øngle on the qbility to manipulate the electrode 2.13 Incomplete Joint Penetration

\

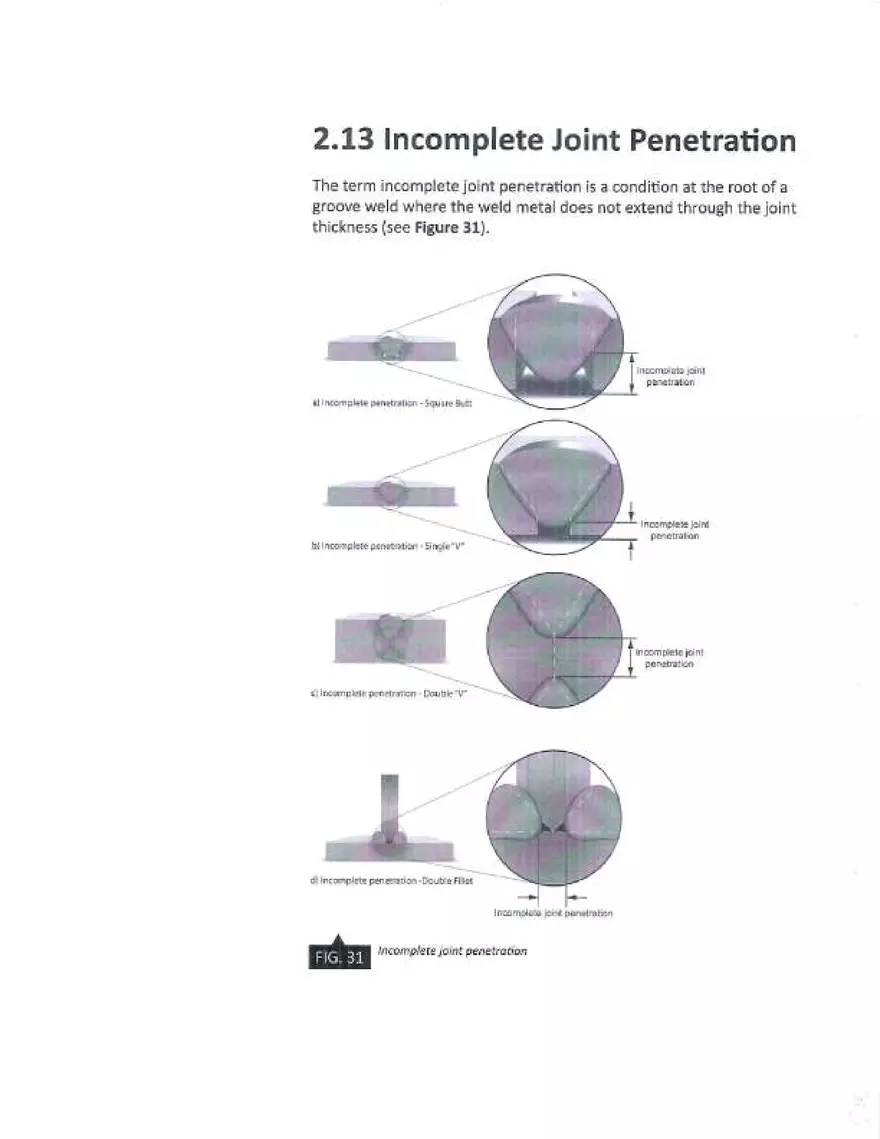

The term incomplete joint penetration is a condition at the root of a

groove weld where the weld metal does not extend through the joint

thickness (see Figure 31).

z= S

_

lỀ —

—<—

—.

Incomplete joint

penetration

a) Incomplete penetration - Square Butt

Pu

—<

NI

mu

Incomplete joint

ma

b) Incomplete penetration - Single”V”

penetration

- „—.

—

mi

x*.

iieompielejoii

-

penetration

— =g

im

c) Incomplete penetration - Double”V”

I

HH

d) Incomplete penetration -Double Fillet

—=.

II

Incomplete Jjoint penetration

FiG.21i

Incomplete joint penetrotion ®

WSS Study

CWBI

H

HN

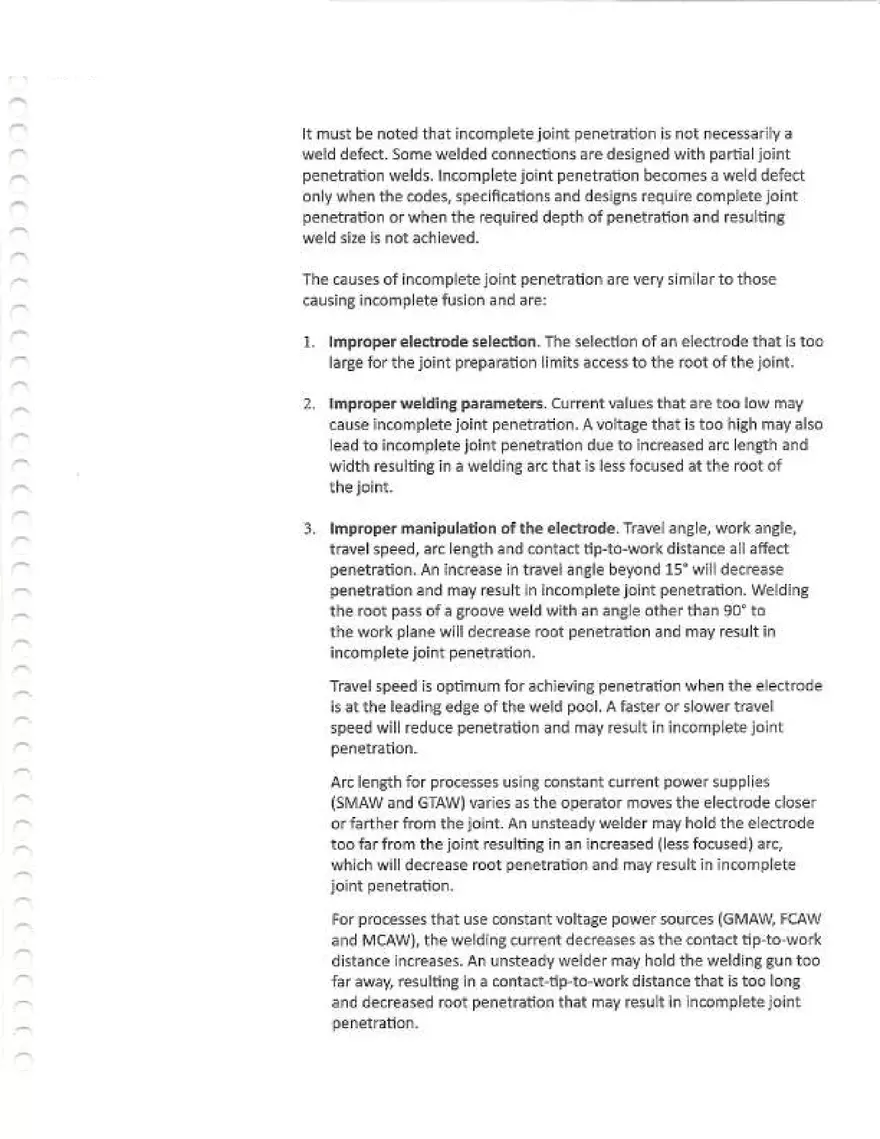

lt must be noted that incomplete joint penetration is not necessarily a

weld defect. Some welded connections are designed with partial joint

penetration welds. Incomplete joint penetration becomes a weld defect

only when the codes, specifications and designs require complete joint

penetration or when the required depth of penetration and resulting

weld size is not achieved.

The causes of incomplete joint penetration are very similar to those

causing incomplete fusion and are:

1.

Improper electrode seleciion. The selection of an electrode that is too

large for the joint preparation limits access to the root of the joint.

2.

Improper welding parameters. Current values that are too low may

cause incomplete joint penetration. A voltage that is too high may also

lead to incomplete joint penetration due to increased arc length and

width resulting in a welding arc that is less focused at the root of

the joint.

3.

Improper manipulation of the electrode. Travel angle, work angle,

travel speed, arc length and contact tip-to-work distance all affect

penetration. An increase in travel angle beyond 15° wiïll decrease

penetration and may result in incomplete Jjoint penetration. Welding

the root pass of a groove weld with an angle other than 90° to

the work plane will decrease root penetration and may result in

incomplete joint penetration.

Travel speed is optimum for achieving penetration when the electrode

is at the leading edge of the weld pool. A faster or slower travel

speed will reduce penetration and may result in incomplete Joint

penetration.

Arc length for processes using constant current power supplies

(SMAW and GTAW) varies as the operator moves the electrode closer

or farther from the joint. An unsteady welder may hold the electrode

too far from the joint resulting in an increased (less focused) arc,

which will decrease root penetration and may result in incomplete

Joint penetration.

For processes that use constant voltage power sources (GMAW, FCAW

and MCAW), the welding current decreases as the contact tip-to-work

distance increases. An unsteady welder may hold the welding gun too

far away, resulting in a contact-tip-to-work distance that is too long

and decreased root penetration that may result in incomplete joint

penetration.

Related Documents

- ERGY8070. Week 4: Practice Problems

- ERGY8070. Week 3: Practice Problems

- ERGY8070. Week 2: Practice Problems

- Motion in a Plane

- Multiplication of Vectors

- Newtons Second Law of Motion

- Introduction to Projectile Motion

- Parallelogram Law of Vector

- ERGY8070. Week 1: Practice Problem

- Work, Work done by constant and variable force

- Unit Vector

- Uniform Circular Motion

- Rectangular Components

- Addition Of Vectors

- Newtons Third Law of Motion

- Motion of a car on level road

- Law of Inertia - Newtons First Law of Motion

- Friction

- Equilibrium of Concurrent Forces

- Centripetal Acceleration

Report

Tell us what’s wrong with it:

Thanks, got it!

We will moderate it soon!

Report

Tell us what’s wrong with it:

Free up your schedule!

Our EduBirdie Experts Are Here for You 24/7! Just fill out a form and let us know how we can assist you.

Take 5 seconds to unlock

Enter your email below and get instant access to your document